BIOCERAM AZUL

| Item | Unit | BIOCERAM AZUL | Zirconia (BIOCERAM ZR195) |

High‐purity aluminum (BIOCERAM AL190) |

Co-Cr-Mo alloy |

|---|---|---|---|---|---|

| Chemical composition | wt% | Al2O3 79.3, ZrO2 18.2, Others 2.5 |

ZrO2+HfO2+Y2O3>99.0 | Al2O3>99.5 | Co Bal, Cr 26-30, Mo 5-7 |

| Density | g/cm3 | 4.24 | 6.08 | 3.98 | 8.5-10.0 |

| Average crystalline particle diameter | μm | 0.4 | 0.2 | 1.3 | - |

| Four-point bending strength | MPa | 1400 | 1450 | 600 | 655 |

| Fracture toughness value (IF method) | MPa・m0.5 | 4.5 | 3.8 | 3.4 | - |

| Hardness | Hv | 1740 | 1400 | 1900 | 285-340 |

| Young's modulus | GPa | 350 | 210 | 400 | 213 |

* The bending strength of a metallic material indicates tensile strength as a reference value.

The mechanical properties of BIOCERAM AZUL, BIOCERAM ZR195, and BIOCERAM AL190 were compared in terms of four-point bending strength, fracture toughness (IF-method), and hardness. As shown in the graphs below, BIOCERAM AZUL has strength and fracture toughness similar to that of zirconia (BIOCERAM ZR195), and hardness similar to that of high-purity alumina (BIOCERAM AL190). The results demonstrate the characteristics of BIOCERAM AZUL with three types of strength, toughness, and hardness.

Based on an investigation by Kyocera’s research department

Based on an investigation by Kyocera’s research department

Based on an investigation by Kyocera’s research department, a fracture strength comparison test was carried out using BIOCERAM AZUL, BIOCERAM ZR195, and BIOCERAM AL190 Femoral heads (28+3). BIOCERAM AZUL showed higher strength than BIOCERAM AL190.

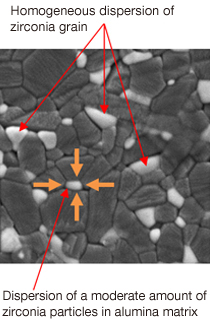

BIOCERAM AZUL has succeeded in achieving high strength, toughness and hardness by strictly controlling the alumina/zirconia ratio based on alumina materials and evenly dispersing zirconia particles.

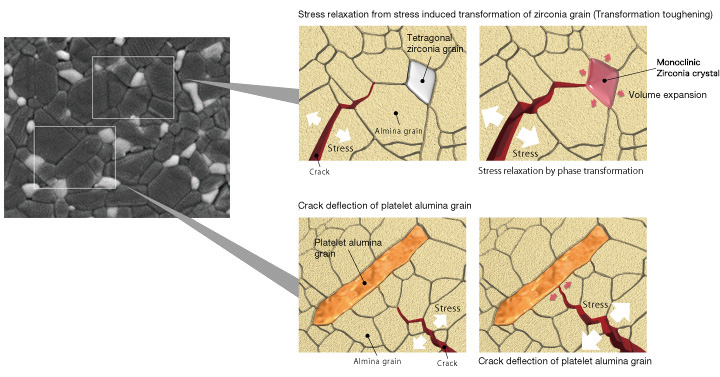

BIOCERAM AZUL has a high strength and toughness due to the uniform dispersion of fine crystalline grains and zirconia grains. Stress relaxation from zirconia particles and a crack bypass effect from alumina plate crystal are also considered to be factors promoting high strength and toughness.

In general, zirconia undergoes an evident phase transition to monoclinic crystals at temperatures around 200-300 °C, which is reported to be accelerated by the presence of moisture. Therefore, there are concerns about the change in the crystalline phase of zirconia due to the inclusion of zirconia in the materials in BIOCERAM AZUL. However, BIOCERAM AZUL maintains tetragonal crystals due to the constraints of alumina particles through ingredient compounding and crystal control techniques. Also since there is no aggregation of voids and zirconia particles, it is stable in hydrothermal environments.

Phase transition of zirconia

BIOCERAM AZUL aging test: Calculation of monoclinic

quantity in water vapor saturated at 134°C: X-ray diffraction →

Garvie and Nicholson equation

To investigate the change in the crystalline phase of zirconia in BIOCERAM AZUL, an aging test was conducted in saturated water vapor at 134℃ for 10 hours and 50 hours. The results showed almost no significant change in the crystalline phase of zirconia for BIOCERAM AZUL.

A four-point bending strength test of BIOCERAM AZUL under hydrothermal conditions showed no change in BIOCERAM AZUL flexural strength. Due to this characteristic BIOCERAM AZUL is stable in vivo.

Tested in combination with GP liner

To evaluate the wear properties of the BIOCERAM AZUL head, wear tests were conducted using HIP simulators and the results were compared with those of existing products (CoCrMo alloy).