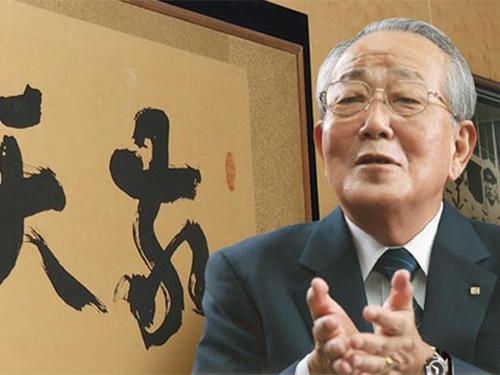

Today, we're excited to introduce Yoshiyuki Takakura, a Production Technology Engineer at KYOCERA Industrial Tools Corporation. Yoshiyuki's primary responsibilities lie in in-house equipment manufacturing and productivity improvement. He is deeply involved in the design and manufacturing of equipment and jigs for Kyocera's power tool production lines. Beyond that, he contributes to technical support and operating improvement activities at our manufacturing sites in China and works on production transfer projects to Southeast Asia.

Currently, he is challenging himself to deepen his expertise in motor manufacturing processes and equipment. A significant portion of the motors used in Kyocera's power tools are produced in-house and custom-designed for each specific tool. This critical process requires a high level of knowledge in both manufacturing processes and the corresponding production equipment. Yoshiyuki is actively working to acquire this specialized technical knowledge under the guidance of his senior colleagues, ensuring a high quality and efficiency for our core components.

He is passionate about continuously expanding his technical skills and contributing to manufacturing excellence.

Outside of work, Yoshiyuki enjoys hands-on activities like tinkering with machines, repairing his beloved old car, and DIY woodworking. His latest project idea involves turning a factory-grade speaker into an original alarm clock - combining his passion for engineering with a touch of creativity!

Currently, he is challenging himself to deepen his expertise in motor manufacturing processes and equipment. A significant portion of the motors used in Kyocera's power tools are produced in-house and custom-designed for each specific tool. This critical process requires a high level of knowledge in both manufacturing processes and the corresponding production equipment. Yoshiyuki is actively working to acquire this specialized technical knowledge under the guidance of his senior colleagues, ensuring a high quality and efficiency for our core components.

He is passionate about continuously expanding his technical skills and contributing to manufacturing excellence.

Outside of work, Yoshiyuki enjoys hands-on activities like tinkering with machines, repairing his beloved old car, and DIY woodworking. His latest project idea involves turning a factory-grade speaker into an original alarm clock - combining his passion for engineering with a touch of creativity!