※We have discontinued the sale of this product as of April 2022. The successor model is "KJ4B-EX1200-RC".

URL: https://global.kyocera.com/newsroom/news/2024/000842.html

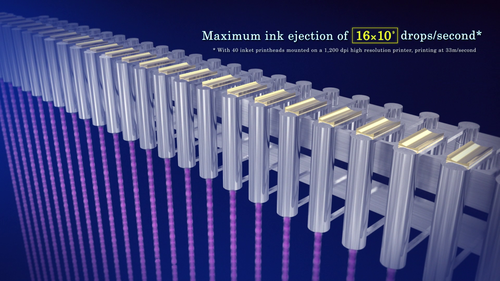

Kyocera Corporation has announced the development of a next-generation inkjet printhead offering high-speed, high-resolution printing for a wide range of printing applications, with a focus on graphics. Kyocera's Model KJ4B-EX 1200 printhead will be available in December 2020.

* You can scroll this table sideways.

| Model | KJ4B-EX1200 | Maximum jetting frequency | 80 kHz |

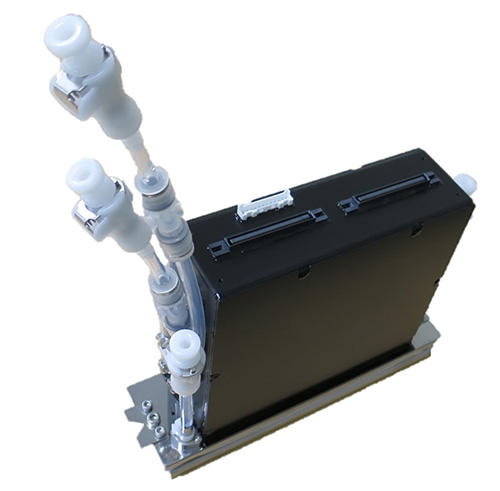

| Dimensions | 200 x 52 x 141.1 mm (Width x Depth x Height) |

Maximum drop volume | 2.8 pl |

| Maximum print speed | 100 m/min | Minimum drop volume | 1.5 pl |

| Resolution | 1200dpi | Compatible ink | Aqueous |

| Effective print width | 108.27 mm | Development facility | Kagoshima Kokubu Plant |

Kyocera's KJ4EX series of printheads utilize large integrated piezo actuators*1 that enable higher-resolution printing by homogenizing image quality inside the printhead. The series' first model, the 600dpi KJ4B-EX600 printhead, has been available since April 2020.

The KJ4B-EX 1200 is Kyocera's latest model for a wide range of printing applications, with a focus on graphics. Its 1200-dpi ink recirculation structure achieves high-resolution printing with 25% faster print speed than conventional models*2. Kyocera plans to gradually expand its lineup to include larger-drop-volume and UV compatible models.

*1 components that generate ink-jetting power using the piezoelectric effect of fine ceramics

*2 Kyocera's conventional products (ink non-recirculation model)

Development Background

Demand for digital printing continues to grow due to its productivity advantages and the environmental benefits realized by eliminating the need for printing plates, plate-cleaning chemicals, and liquid waste. Digital printing is being used not only for printing on paper, but also for a wide range of non-traditional media, including clothing, food packaging, and housing construction materials. Inkjet technology for these diverse media requires high-speed, high-resolution, and high durability printheads.

Main Features

1. Newly developed integrated piezo actuator achieves high resolution

| Kyocera developed a large integrated piezo actuator using its proprietary material design technology for dense polycrystalline ceramic actuators and manufacturing process technology for thin piezoelectric ceramic substrates. By using a single large, integrated piezo actuator instead of multiple piezo actuators per printhead, Kyocera's new design allows image homogenization within the printhead and achieves higher resolution. |  |

2. Faster jetting frequency and improved jetting stability

| By optimizing the ink channel design and the head structure, Kyocera has improved the printhead's maximum jetting frequency and ink-jetting stability. The maximum jetting frequency has been increased to 80 kHz, which is 25% faster than conventional models, enabling single-pass printing at up to 100 m/min when printing in the 1200 dpi feed direction. |  |

3. Simpler, robust laminated structure for higher durability

Integrated piezo actuators allow for a simple and robust structure, which improves the strength, stability, and durability of the printhead.

4. Higher-definition image quality with stable jetting of smaller droplets

| By incorporating an analog waveform circuit capable of achieving drive waveforms of arbitrary shapes, Kyocera's design generates a driving waveform suitable for stable ejection of extremely small droplets with a volume of just 1.5 pl. In addition, the influence on the jetting characteristics is minimized to attain stable, continuous high-speed printing by equipping a water-cooling structure to prevent the thermal environment of the circuit from influencing the temperature of the jetting component. |  |