- Products

- Chemical Products

- Electrical/High Thermal Conductive Paste

- Ag Sintering Paste for Die-attach

Chemical Products

Ag Sintering Paste for Die-attach

Features of Ag Sintering Paste

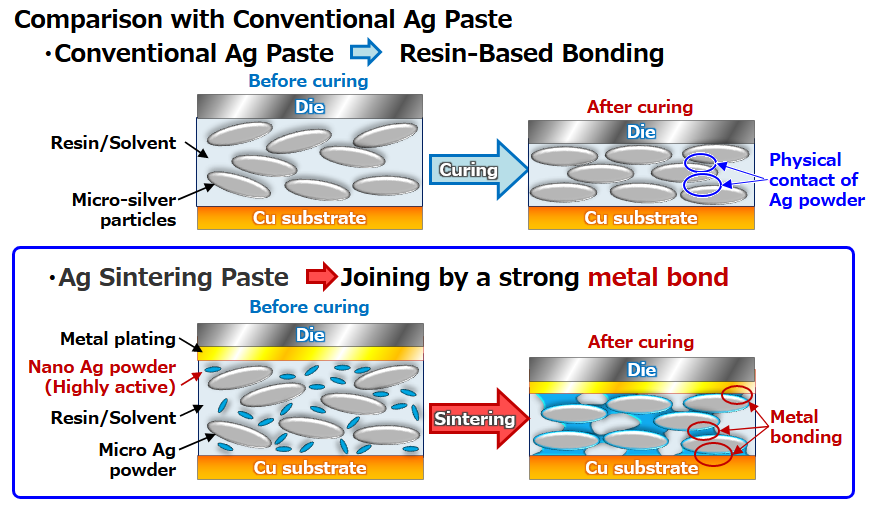

High bonding strength by metal sintering with nano Ag and micron Ag powders

・Low electrical resistance

・High thermal conductivity

・Unique resin dispersion system for achieving high heat resistance and reliability with low stress (exhibits high bonding reliability even at 250°C)

Comparison with Conventional Ag Paste

The bonding process of Ag sintering paste

・Utilization of existing equipment is possible

Pressure-less bonding

Same application method as conventional Ag paste

・Apply low temperature 200-250°C for sintering

・Curing in air or nitrogen atmosphere

Pressure-less bonding

Same application method as conventional Ag paste

・Apply low temperature 200-250°C for sintering

・Curing in air or nitrogen atmosphere

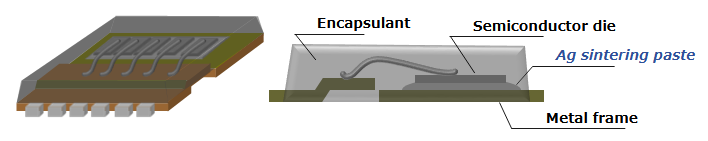

Applications of silver sintering paste

【For Solder Replacement】

・Substitution for high-temperature lead solder

・Substitution for AuSn solder

・Substitution for high-temperature lead solder

・Substitution for AuSn solder

【Devices】

・SiC/GaN power devices (TO packages, power modules)

・Vertical-cavity surface-emitting lasers (VCSEL)br>・High-power LEDs

・SiC/GaN power devices (TO packages, power modules)

・Vertical-cavity surface-emitting lasers (VCSEL)br>・High-power LEDs

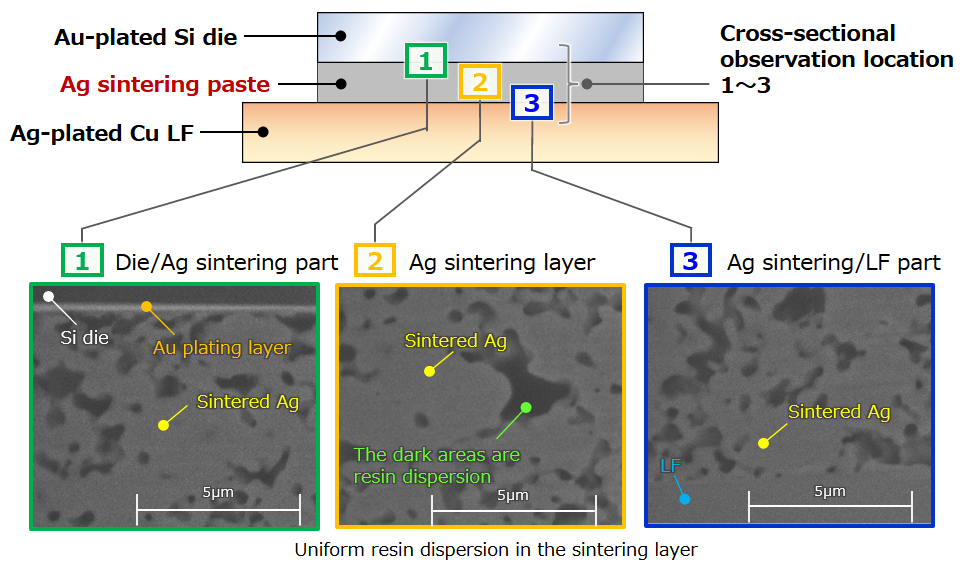

Cross-Sectional Observation of the Sintering Layer

Bonding Reliability Test (Comparison with various soldering methods)

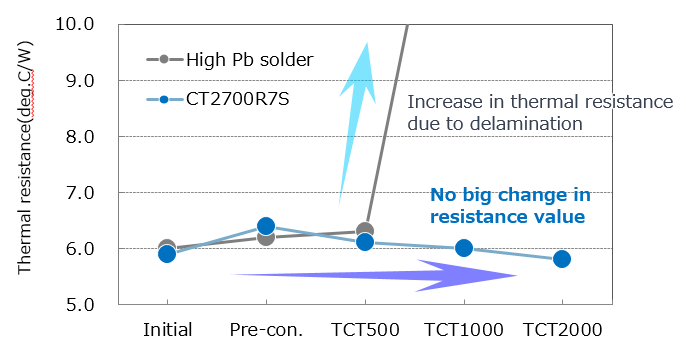

Thermal Resistance Change by Thermal Cycle Test (-55°C/150°C)

Test conditions(Data provided by the customer)

PKG:HQFP

Die:6.0x6.0x0.4mm (BM:Au)

LF: Ag-plated Cu LF

Pre-condition: MSL1 (260°C/10s, 3 times)

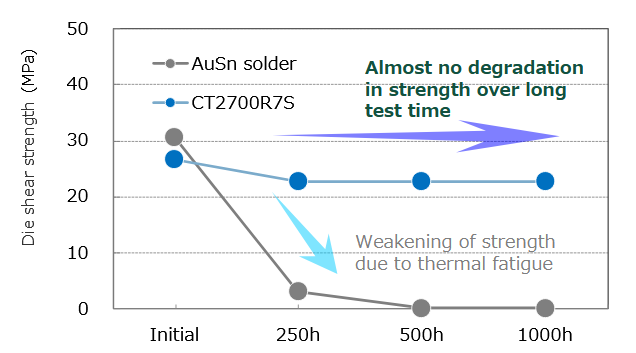

Shear Strength Change (at 250°C high-temperature exposure)

Test conditions(In-house testing)

Die:4.0x4.0x0.3mm (BM:Au)

LF:Pd-PPF

Measurement temperature:260°C

Related Products