Creating a Decarbonized

Society with Renewable Energy

Smart Energy Production Division,

Corporate Smart Energy Group

Anyone can contribute to

sustainability if they try

― Tell us a little about your current work.

I design new production lines for solar cells*1 and modules*2 and manage existing production lines. I pursue efficient, highly productive manufacturing lines by analyzing manufacturing processes and work content to refine and improve problems. I’m currently involved in optimizing personnel and material flow lines by checking equipment positions and passages to revise production spaces and rebuild production lines.

I also participate in the IT Promotion Committee composed of members from all sections of the Smart Energy Production Division (“SE Production Division”) and work to solve problems using digital technologies, such as Information and Communication Technology (ICT), to improve operating efficiency and implement automation solutions for routine work. For example, tasks that had to be handled by going to the manufacturing site, such as repairing the production line program, can now be managed remotely quickly and efficiently by connecting production equipment to a network. We can also monitor the equipment’s operating rate and the number of goods produced.

*1: The smallest unit size for a solar panel

*2: Single-panel units combining cells

― What are some of the sustainability goals the SE Production Division is working toward?

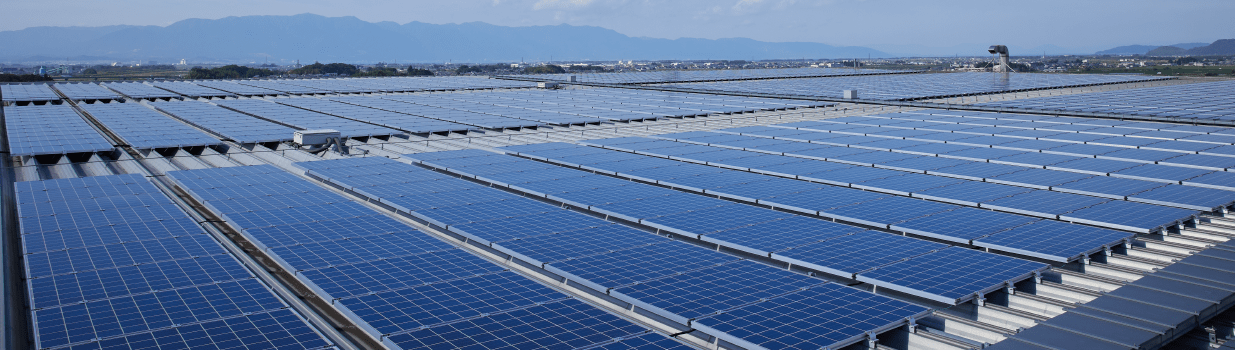

Kyocera is working to realize a decarbonized society using technical know-how developed over our approximately 50 year-long history in the solar business.

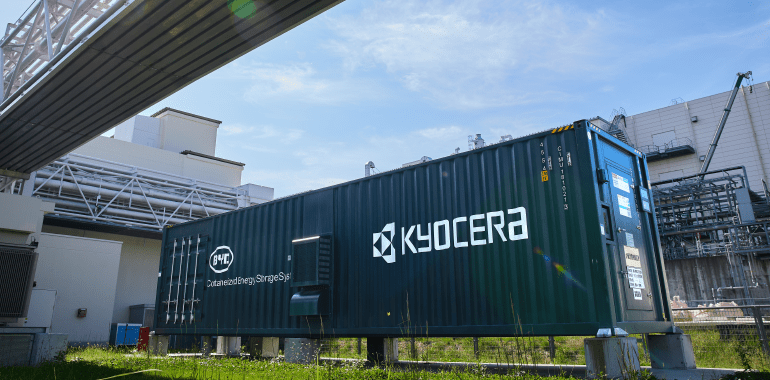

More recently, in July 2020, Kyocera began a proof-of-concept test for a renewable energy self-wheeling*3 system using storage batteries. This test supplies renewable energy generated by a Kyocera-produced solar power system installed on city land (2,000 m2) in Yasu, Shiga, to Kyocera’s own Shiga Yasu Plant about 2 km away via the Kansai Electric Power Company’s distribution network.

Society uses various sources to generate electric power, like thermal and nuclear power. However, currently, Japan is carrying forward with a policy to make renewable energy the country’s primary power source. Through this test, Kyocera is contributing to building a stable, suitable structure for energy supply and demand and making efforts toward developing a stable, sustainable smart city and microgrid in cooperation with local communities.

*3: A system in which electric power generated by a company at its own premises is supplied to its other premises using a power grid operated by a public utility

― What made you interested in sustainability and the global environment?

I started camping at the suggestion of my senior at work. However, while camping, I frequently see trash that has been left behind or that has floated ashore the rocky embankments and beaches along Lake Biwa in Siga Prefecture, Japan, where I often visit. In recent years, I’ve learned through the news about the effects of ocean waste, particularly microplastics, on sea creatures and the environment, and I started thinking about whether we can create a win-win relationship between marine life, humans, and the Earth.

This sort of thing inspired me not just to pick up trash I see on the lakeshore but also to learn as much as possible about how not to create garbage, such as by bringing reusable chopsticks or cutting ingredients at home when I go camping.

In everyday life, I also bring a water bottle to work to try not to create plastic bottle trash. I also deliberately began carrying a reusable shopping bag. Choosing a handmade or stylish bag for its design or function is fun, too. Of course, these are all small steps, but I feel anyone can contribute to sustainability if they try.

I want to contribute to a society that can use stable green energy

― What kind of sustainability activities do you feel members of Generation Z, yourself included, are looking for from companies? And what kind of sustainability goals do you think Kyocera is uniquely able to achieve?

In October 2020, the Japanese government announced its goal to realize a decarbonized society by 2050. With this in the background, I feel the awareness of decarbonization has increased in our generation. As a company in the manufacturing industry, I think that Kyocera is also required to curb carbon dioxide emissions.

Kyocera’s strength is that we have developed a wide range of projects, not limited to solar power, and we understand customer needs in those respective areas. Those needs include needs tied to sustainability, too. Continuing to respond honestly to customer needs will lead to the acceleration of Kyocera’s sustainability activities.

― What expectations has the company made of the junior employees who will be responsible for society in the future?

Kyocera is thorough in training junior staff and creating a system that allows them to be active.

On the point of training, especially, we get to participate in training sponsored by various Kyocera Group companies and are supported when taking qualification tests. We are also carefully guided through a solid support system to handle the digitalization of operations that’s picking up speed now at Kyocera.

― Please tell us about your goals and dreams regarding the SE Production Division’s and your own subsequent sustainability activities.

Many people understand that realizing a decarbonized society is necessary to protect the global environment. However, looking at the current adoption rate of solar panels to residences, I think people are still hesitant to take action themselves. Kyocera’s product are highly reliability and offer long service life, but even if the products are good, it isn’t very meaningful if people won’t use them. I can help resolve this issue by reducing production costs with labor-saving and efficient production lines. My goal is to create a society where people around the world can have access to safe, stable, and cheap renewable energy.

Kyocera's initiatives for the future

RE100 Initiative

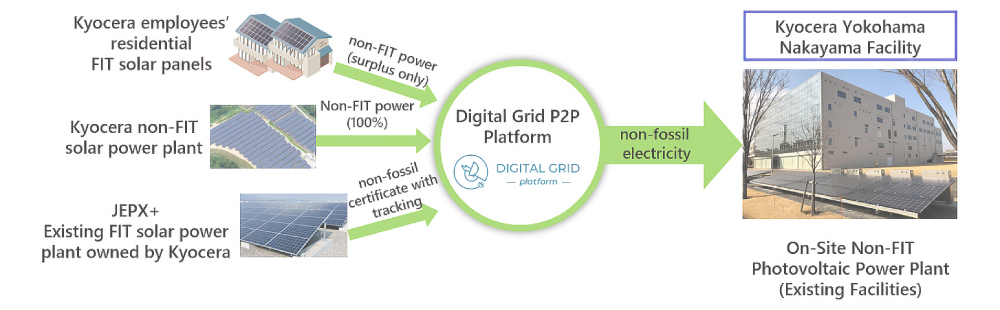

Kyocera and Digital Grid Corporation are carrying out a demonstration test of renewable peer-to-peer (P2P)*4 electric power transactions at our Yokohama Nakayama Office. In this demonstration test, surplus power from former FIT solar panels installed at the homes of Kyocera employees and power from Kyocera's newly-built non-FIT solar power plant in Asahi, Chiba Prefecture, is adjusted by a Digital Grid Platform and supplied to our Yokohama Nakayama Office. This office also utilizes power from its existing on-site non-FIT solar power plant. If the combined electrical power is insufficient to meet demand, any shortfall will be supplied by power purchased from the Japan Electric Power Exchange (JEPX) with non-fossil-fuel energy certificates and tracking information from Kyocera's existing FIT photovoltaic power plant. This demonstration test means that all of the electricity consumed by the Yokohama Nakayama Office will come from solar energy.

*4: • Peer-to-peer (P2P) electric power transactions make use of advanced technologies that utilize AI, for example, to predict power generation output, collect power from sources such as residential homes and/or business facilities that own solar installations and storage batteries, and then supply that power to homes and other points of variable electric power demand.