Kyocera's inkjet printheads fulfill a wide variety of requirements - including superior jetting performance - by combining our proprietary Fine Ceramic materials and advanced flow-channel design technologies.

-

High-performance piezoelectric actuators produce ultra-high-speed printing through Kyocera's unique Fine Ceramic technologies.

-

Flow-channel design technology allows a wider printhead with high resolution.

-

Stainless-steel laminated structure ensures robust operation in demanding industrial applications.

01:High-performance piezoelectric actuators produce ultra-high-speed printing through Kyocera's unique Fine Ceramic technologies.

Kyocera has developed a large, monolithic piezoelectric actuator using proprietary material-design technologies. Combined with advanced manufacturing technology, this allows extremely thin piezoelectric ceramic substrates - eliminating the conventional need for several actuators per printhead, and ensuring uniform image quality for vivid colors and sharp detail.

・Achieves high-speed response using piezoelectric displacement

High-speed response is essential to the performance of inkjet printheads in the digital printing market. Kyocera's actuators are developed with our own proprietary technology to ensure high-speed printing and high productivity, fulfilling the need for high-speed nozzle control with the instantaneous-response characteristics of piezoelectric ceramics.

・High durability ensured through Kyocera's decades of leadership in Fine Ceramics technology

The piezo actuator is generally considered to offer durability exceeding that of a thermal inkjet system.

Kyocera's highly durable piezo actuators resist deterioration even after extended use, thanks to

our unique ceramic technology.

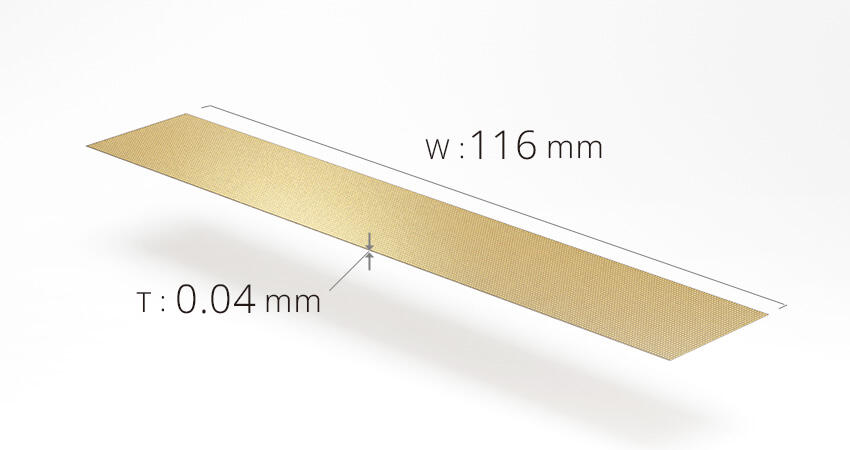

・Large, thin piezoelectric actuator facilitates high-definition printing

Kyocera's piezo actuators can be over 100 mm in length or width, yet only 0.04 mm thick, with extreme dimensional uniformity to ensure reliable operation. They contribute to high-definition printing through densely-arranged driving elements manufactured with extreme precision and ceramic manufacturing technology cultivated over many years.

02:Flow-channel design technology allows greater printhead width and resolution.

Wider print capability reduces the number of printheads required in large-format printing. Kyocera technology offers print widths up to about 4 inches, reducing the labor required for printhead positioning and adjustment, and dramatically simplifying piping and channel design for printers.

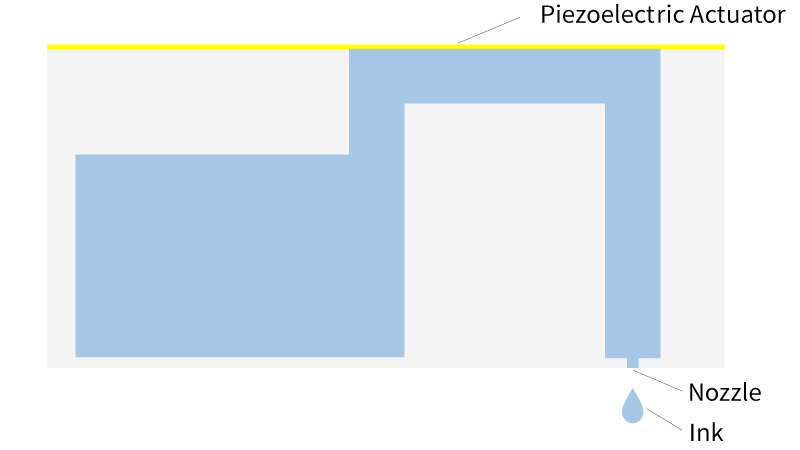

Diagram of Flow Channel

Diagram of Flow Channel・Flow-channel design technology

Kyocera's design technology involves extensive fluid simulation to find the optimal flow channel that can maximize desired jetting characteristics and optimize inkjet printhead performance.

・Flow-channel manufacturing technology

Kyocera has succeeded in creating inkjet printheads with greater width and resolution through advanced monozukuri (manufacturing) capabilities. We can make high-precision components with micron-level dimensional accuracy and 2,500 to 5,000 individual flow channels.

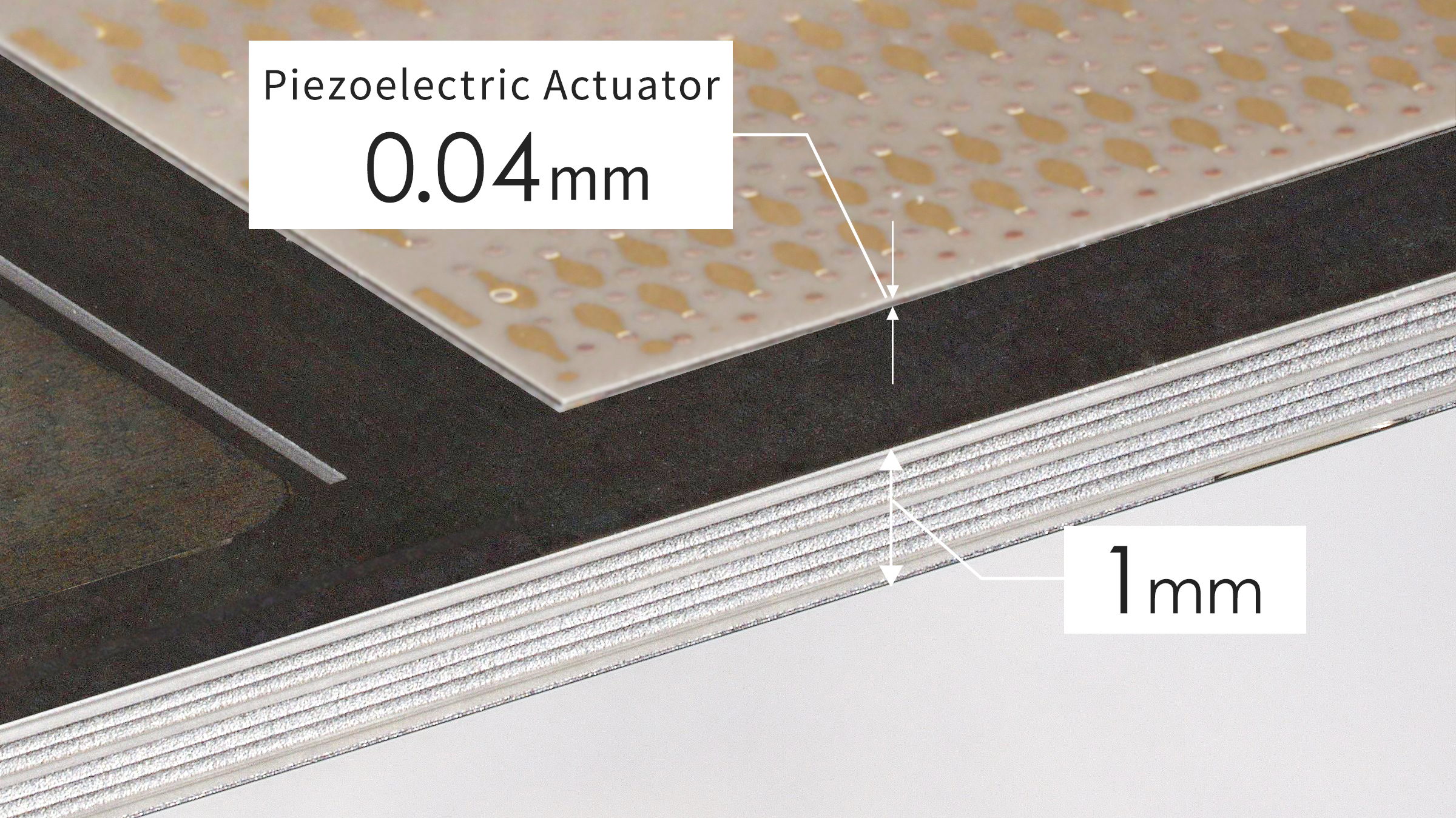

03:Stainless-steel lamination provides stable operation and robustness for industrial applications.

Lamination of stainless-steel parts ensures outstanding robustness to allow stable continuous printing in extended use.

・High chemical resistance and robustness achieved through stainless steel lamination

High chemical resistance is achieved by constructing the ink-flow channel with laminated stainless-steel parts.

As a result, Kyocera's inkjet printheads are compatible with a wide variety of ink. The metal lamination's high resistance to physical impact and deformation ensures high robustness.

・Internal filters in the flow channel prevent foreign particles from entering the nozzles

A fine particulate filter in the flow channel prevents foreign materials from entering the nozzles, reducing a common source of print-performance degradation.

・Internal heater compensates for ambient temperature fluctuation

Kyocera's inkjet printheads include an internal heater as a standard feature to compensate for changes in ambient temperature during printing.