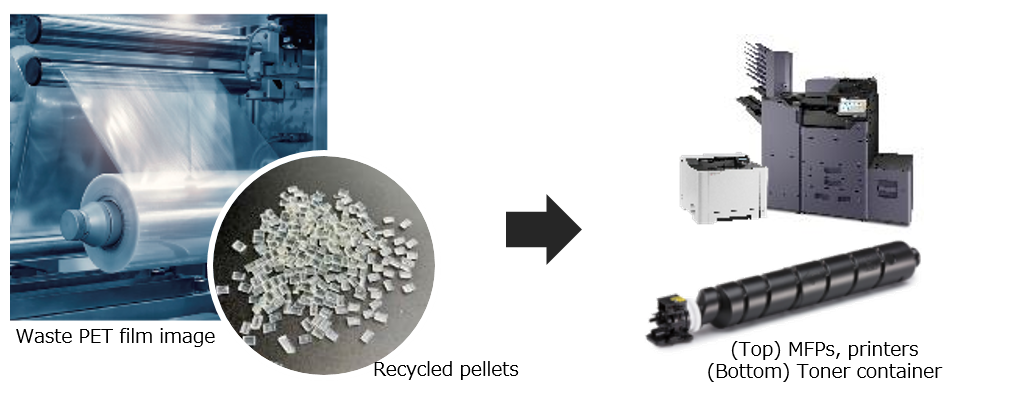

Kyocera Document Solutions Inc. (President: Hironori Ando) announced that it has become the first company*1 in the industry to establish technology for upcycling PET film used in the manufacturing process of multilayer ceramic chip capacitors (MLCC) manufactured by Kyocera Corporation (President: Hideo Tanimoto) into components for MFPs and printers.

Until now, the PET film used in the MLCC production process has been incinerated despite the problem that the only treatment method is thermal recycling*2, which emits CO2 as industrial waste. As a result, approximately 5,500 tons of CO2 were emitted annually as an environmental burden. In cooperation with Kyocera's Electronic Components Division, which manufactures MLCC, Kyocera Document Solutions Inc. has established a technology to convert PET film scheduled for disposal into recycled PET materials for use in MFPs and printers.

*1 Data from the MFPs and printers industry (https://mfd.jbmia.or.jp/members/) as of September 2024, according to Kyocera Document Solutions Inc.

*2 Thermal recycling refers to a recycling method in which "thermal energy" generated during the incineration of waste is recovered and used.

The parts to be converted this time include cases (toner containers) for filling toner, which is a consumable part of MFPs and printers. We aim to replace them with toner containers made from recycled materials. This upcycle will enable PET film to be reborn as a component for MFPs and printers without being discarded. In the future, we will expand the use of recycled materials not only for toner containers but also for internal and external parts, aiming to increase the use of recycled materials to 50% per product.

Kyocera Group places the three principles of "Living Together" - "Coexistence with Society," "Coexistence with the World," and "Coexistence with Nature" as the basis of all corporate activities, and is working on "Environmental Management" to achieve sustainable development while pursuing both ecology (environmental performance) and economy (economic performance).

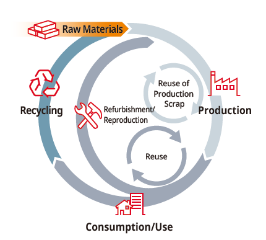

In particular, around the world there is growing interest in the circular economy, a new economic system in which products and raw materials that have been discarded in the course of economic activities are regarded as "resources," and resources are recycled and reused. Kyocera Group is also actively engaged in resource recycling activities that transcend divisions with the aim of achieving zero waste, and this is the first time within the Kyocera Group that an upcycle has been achieved. Kyocera Group will continue to contribute to the development of a sustainable society through such initiatives.

The circular economy concept