Kyoto, 20th June 2024. Kyocera Corporation announced that it has developed a new cut-off solution, "KGZ", for small parts machining.

| Product name | Cut-off solutions for small parts machining "KGZ" |

| Number of models |

Insert: 129 models Toolholder Internal coolant: 24 models Standard type: 70 models For sub-spindle tooling: 18 models |

| Price | Please contact our sales representatives |

| Maximum cutting diameter | 51 mm |

| Edge width | 1.3 / 1.5 / 2.0 / 3.0 mm |

| Chipbreakers |

Chip control oriented: PF / PM / PH Sharp edge: PG |

| Recommended workpieces | Carbon steel, alloy steel, stainless steel, cast iron, aluminum alloy, brass |

Small parts machining involves cutting into the center of the workpiece with an insert that has a cutting width of several millimeters. Therefore, the load on the tool is large, and the generation of chatter and breakage of the holder are major problems. In addition, there are some challenges regarding the workability of the machine, such as the need for a skilled operator to quickly and accurately replace and install inserts in a narrow space.

"KGZ" uses a newly developed clamp structure with three unique mechanisms to firmly lock the insert in place to suppress chatter and achieve stable machining. In addition, the constraint surface of the holder, which is easily subjected to machining load, has a shape that distributes stress, improving durability and realizing high-efficiency machining. In addition, the new insert has a redesigned V-shape groove structure on the top surface to improve restraint and workability.

Also, within the insert grades lineup, a newly developed PVD coated grade, "PR 20 series," for the KGZ was released. The new coating, "MEGACOAT®*1 NANO EX," which is resistant to oxidation and abrasion caused by cutting heat, achieves high precision, long tool life, and stable machining of steel, stainless steel, and cast iron.

*1 "MEGACOAT" is a registered trademark of Kyocera Corporation.

Features of "KGZ"

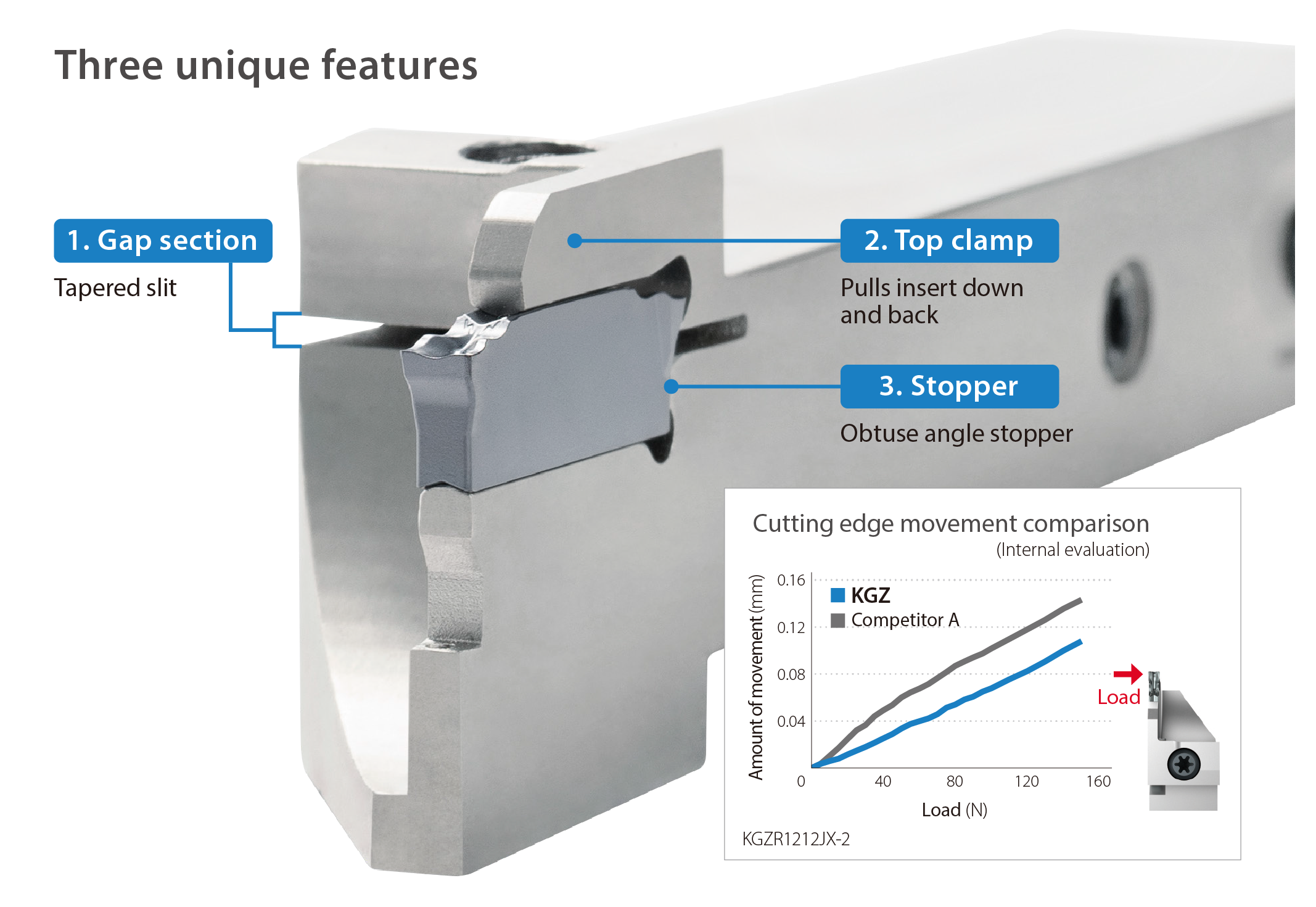

1. Stable and high-efficiency processing is achieved with a clamp structure equipped with three unique mechanisms.

1) Gap section: Press down on the insert from directly above to firmly secure in place.

Generally, it is structurally difficult to fix the insert directly above with a cut-off tool. KGZ has a tapered slit with a slanted cut, so when the fastening screw is tightened, it applies a restraining force from directly above the insert, effectively securing it in place.

2) Top clamp: Pulls the insert inward to increase the binding force.

Designing the shape so that force is applied inward when clamping the insert suppresses the displacement of the insert in the front and rear directions.

3) Stopper: Disperses stress over a large area and improves the durability of the holder.

KGZ uses a stopper as part holder blunt to create a large surface to receive the load and impact from the insert and disperse stress on the holder. As a result, the wear amount of the stopper is reduced to about one-third*2 that of other companies' products. The improved durability of the holder also enables it to withstand high-efficiency processing with high processing loads.

*2 Comparison of holder damage after 100,000 cuts (comparison conducted by Kyocera).

2. Unique V-shape groove improves restraining force and ease of fitting of the insert.

The V-shape groove on the upper surface of the insert has different angles and shapes at both ends and the center, which improves the restraining force and ease of installation.

1) Insert groove end

The ends are made more acute than the central part of the groove. This design helps to reduce the play during insert installation and makes it easier for the insert and holder to fit together correctly, therefore preventing incorrect insertion and contributing to improved workability in narrow spaces.

2) Center of groove

The central part increases the angle of the groove and improves the restraint force of the insert by receiving the clamping force from the upper direction on a large surface.

3. Newly developed insert grades "PR20 series" uses a special nano-layered coating, "MEGACOAT® NANO EX," to enable high-precision, long-life, and stable processing of steel, stainless steel, and cast iron.

Along with KGZ, Kyocera simultaneously released a new PVD coating, "PR20 Series,"*3 specialized for grooving and cut-off processing. A special nano-layered coating, "MEGACOAT® NANO EX for Grooving / Cut-off," newly developed for the PR20 Series, is born from our unique coating process. This coating offers wear resistance approximately two times*4 better than other companies' products in steel machining comparison because it uses aluminum (Al) as the coating's main materials, which has high-temperature hardness and wear resistance characteristics. The PR20 Series achieves high precision, long tool life, and stable machining as the main insert grades for grooving and cut-off machining of steel, stainless steel, and cast iron.

*3 The "PR 20 Series" is a lineup of 3 grades: PR2015, PR2025, and PR2035.

*4 Machining of S45C (comparison conducted by Kyocera).