CRESCENT VERT Rough Stones

Explore our extensive collection and learn about our innovative method for growing rough stones

that are both beautiful and ethically produced.

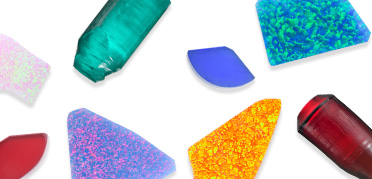

Our Rough Stones

Click to see an enlarged image.

Note: Some stones are now available in ingot form.

Ingot

-

- Ruby -

Avg. size: Φ56×90mm

Avg. weight: 880g

-

- Blue Sapphire -

Avg. size: Φ52×90mm

Avg. weight: 760g

-

- Alexandrite -

Avg. size: Φ55×50mm

Avg. weight: 440g

-

- Green Chrysoberyl -

Avg. size: Φ30×80mm

Avg. weight: 180g

Rough Stone

-

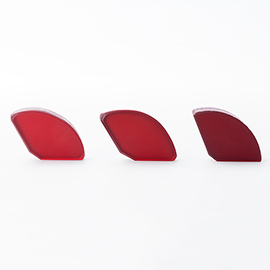

- Ruby - (Medium Dark/Dark/Extra Dark)

Avg. size: 1/3 of a

Φ56mm×15mm(THK) disk

Avg. weight: 40g

Star Ruby also available

- Ruby -

(Medium Dark/Dark/Extra Dark)

-

Average size

Rough stone : Φ56mm x 15mm thick disk divided into 3

-

Average weight

Rough : 40g

Star Ruby also available

-

-

- Blue Sapphire - (Light/Medium/Dark)

Avg. size: 1/3 of a

Φ52mm×15mm(THK) disk

Avg. weight: 30g

Star Sapphire also available

- Blue Sapphire -

(Light/Medium/Dark)

-

Average size

Rough stone : Φ52mm×15mm thick disk divided into 3

-

Average weight

Rough : 30g

Star Sapphire also available

-

-

- Pink Sapphire - (Light/Medium/Dark)

Avg. size: 1/3 of a

Φ54mm×10mm(THK) disk

Avg. weight: 25g

- Pink Sapphire -

(Light/Medium/Dark)

-

Average size

Rough stone : Φ54mm×10mm thick disk divided into 3

-

Average weight

Rough : 25g

-

-

- Padparadscha Sapphire -

Avg. size: 1/3 of a

Φ30mm×10mm(THK) disk

Avg. weight: 25g

- Padparadscha Sapphire -

-

Average size

Rough stone : Φ30mm×10mm thick disk divided into 3

-

Average weight

Rough : 25g

-

-

- Orange Sapphire - (Light/Medium)

Avg. size: 1/3 of a

Φ30mm×10mm(THK) disk

Avg. weight: 25g

- Orange Sapphire -

(Light/Medium)

-

Average size

Rough stone : Φ30mm×10mm thick disk divided into 3

-

Average weight

Rough : 25g

-

-

- Alexandrite -

Avg. size: 1/4 of a

Φ55mm×15mm(THK) disk

Avg. weight: 25g

- Alexandrite -

-

Average size

Rough stone : Φ55mm×15mm thick disk divided into 4

-

Average weight

Rough : 25g

The photo on the right is a simulation of the color change effect under UV light.

-

-

- Emerald -

Avg. size:

25mm×15mm×10mm

Avg. weight: 6g

-

- White Opal - (Red Fire/Green Fire)

Amorphous shapes

Avg. weight: 30g

-

- Black Opal - (Red Fire/Green Fire)

Amorphous shapes

Avg. weight: 30g

-

- Pink Opal - (Red Fire/Green Fire)

Amorphous shapes

Avg. weight: 30g

-

- Water Opal - (Red Fire/Green Fire)

Amorphous shapes

Avg. weight: 30g

-

- Fire Opal - (Red Fire/Green Fire)

Amorphous shapes

Avg. weight: 30g

-

- Blue Opal - (Red Fire/Green Fire)

Amorphous shapes

Avg. weight: 30g

* Please note: Depending on your color display settings, the actual color of our gemstones may vary slightly.

* Product image for illustration purposes only. The actual product may vary, so before purchasing, let us confirm a mutual understanding of the color range with the actual sample.

How we grow our gemstones

CRESCENT VERT gemstones are grown exclusively in Kyocera's gem-growing laboratory in Kyoto, Japan. Our proven process, developed over several decades, produces stones with fewer inclusions than mined gemstones. Our high-quality rough stones contain more usable surface area so that our valued customers can produce the largest cut gemstones possible.

-

-

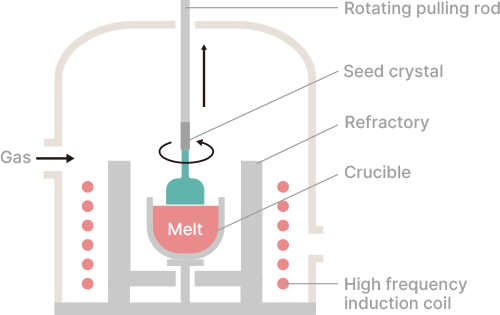

Czochralski Process (CZ Process)

Ruby/ Sapphire/ Alexandrite / Chrysoberyl

Compared to the well-known Verneuil method, which colors only the outer surface of gemstones, the Czochralski method grows beautiful gemstones with a uniform color throughout. An additional advantage of this method is that the large crystals we grow have fewer growth stripes.

-

-

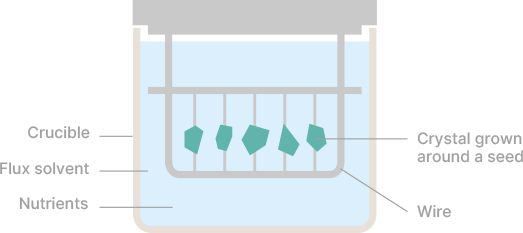

Flux-growth Process

Emerald

Both the flux-growth and hydrothermal processes are popular ways to grow emeralds. Kyocera grows its gems through an advanced method based on flux-growth. We improve crystal quality by allowing more time than the hydrothermal process requires to reduce growth lines and thermal strain in our gemstones.

-

-

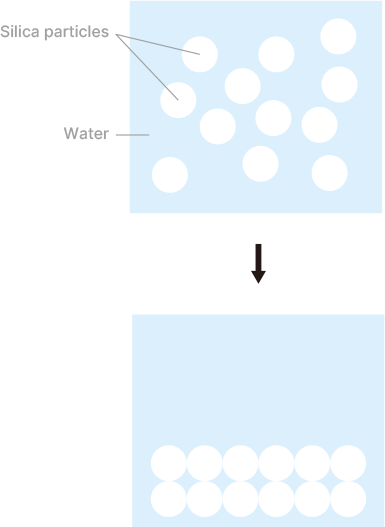

Precipitation

Opal

We grow opal in a carefully controlled environment that enables the round silica particles to precipitate slowly and align both horizontally and vertically in a tight formation. This results in high-quality, stable opal material that can withstand both heat and chemical processes. Our highly controlled laboratory conditions maintain a stable moisture balance in the stones as they grow. This is why our lab-grown opal can be used in a variety of products and designs that natural opal can’t withstand.

Our passion for ethical gemstones

In the largely unregulated mining and gemstone industry, suspected ethical issues include

forced and child labor, organized crime funding, and environmental damage.

Kyocera takes these problems seriously.

As such our process offers an alternative for gemstones produced in a way friendly to people, the environment, and society.

People and Society

-

Our Stance on

Conflict-free GemstonesMining is not required to create CRESCENT VERT Opal and our other lab-grown gemstones. Instead in our sustainable lab-grown gemstone process, we refine raw materials identical to the gem in crystal structure but not pure enough to be called gemstones.

Kyocera has a strict policy against purchasing conflict minerals that might serve as a funding source for armed groups. We also don’t use any other materials or products made using metals that may be mined in a way that poses a risk to human rights.

Please refer to the Kyocera Group’s Conflict Minerals Policy to learn how we comply with OECD due diligence guidelines.

-

Through our lab-grown gemstone process, we avoid contributing to human rights abuses.

Forced labor

Child labor

Criminal activities

-

Grown in Japan

We grow all CRESCENT VERT gemstones in our ISO14001-certified factory in Japan. Only companies that meet the stringent standards of ISO14001 environmental management certification are internationally recognized as conducting business activities to minimize environmental impact.

With genuine care taken for all people and the environment, we hope to spread the benefits of “Japan quality” products around the world.

People

-

We carefully control the raw materials and chemical substances used in the process of producing gemstone to achieve global standards, including REACH and RoHS.

-

Environment

-

The enormous energy consumption and greenhouse gas (GHG) emissions inherent in the rare stone mining process are unknown. In other words, the true environmental impact of the colored gemstone industry remains a mystery.

The Kyocera Group companies recognizes the climate change countermeasures as its critical challenges. Therefore, we plan to achieve our long-term environmental targeting 46% reduction of GHG emissions by FY2031 compared to FY2020 levels through energy conservation measures and renewable energy technologies.

Japan’s Ministry of the Environment specifies six types of GHGs that should be reduced, while five of the six are not used in the gem-growing process, we recognize that our sector’s carbon footprint is relatively smaller than those in other business sectors. We will continue to optimize energy use at both our sales offices and manufacturing sites to minimize the impact of the environment.

-

-

We install solar power generation systems at our facilities in Japan and overseas.

Our Kyoto headquarters, where the jewelry sales division is located, has a solar generation system on its outside wall.

-

-

We produce lab-grown gemstones without mining rare stones. By doing so, we minimize the environmental impacts caused by mining stones, including habitat loss, the spread of disease to animal species, population decline of critically threatened or endangered species, increased conflict between human and wildlife, water quality decline, and the destruction of land and aquatic ecosystems.

Additional environmental issues often result when a factory releases wastewater directly into a body of water.

Our gem-growing laboratory has an advanced wastewater treatment facility to carefully manage any release of water by properly complying with wastewater standards set by the national and municipal governments.

CSR Initiatives and External Evaluation

We participate in and agree to initiatives to increase

ethical actions and sustainability.

-

*1

*1

-

-

In addition, Kyocera's environmental, social, governance (ESG) and compliance activities are evaluated by third-party groups, and our efforts to reduce the environmental burden of our entire value chain are monitored through multiple certifications and selections.

-

*2

*2

-

-

-

*3

*3

-

*1 Since 2011 the Kyocera Group has been committed to the UN Global Compact corporate responsibility initiative and its principles for human rights, labor, the environment, and anti-corruption.

*2 The Kyocera Group obtained a Science Based Targets (SBT) certification from the SBT Initiative, an international environmental organization that evaluated Scope 1,2 and Scope 1,2,3 targets (2°C level) in FY2019. Our application for the 1.5°C level target, updated in FY2022, is currently being assessed by SBT.

*3 S&P Dow Jones Indices/S&P Carbon Efficient Indices:https://www.spglobal.com/spdji/en/landing/investment-themes/carbon-efficient/