Contingency Planning Development

The Kyocera Group has developed a Disaster Countermeasures Manual based on the Disaster Countermeasure Basic Guidelines to minimize human and material damage and ensure prompt business recovery in the event of a large-scale natural disaster. The Disaster Countermeasures Manual includes rules and regulations for collecting and communicating information in the event of a natural disaster, earthquake countermeasures, and wind and flood damage countermeasures.

Basic Disaster Response Policy

Ensuring Safety of Employees and Visitors

Kyocera has established rules for responding to a major earthquake based on the Disaster Countermeasures Manual, and conducts regular and comprehensive disaster drills, including ensuring the safety of visitors and employees. Kyocera has also introduced a system to confirm the safety of employees and their families for those working at home, and has put in place a system to quickly collect information and respond to emergencies. We will continue to provide education and periodic drills to raise awareness of the need for disaster prevention to ensure the safety of employees, including visitors, and others.

Actions to Deal with Earthquakes

To mitigate damage in the event of a major earthquake, Kyocera has installed Earthquake Early Warning receivers at each of its sites and introduced a damage assessment system linked to a safety confirmation system, including drills when an Earthquake Early Warning is issued, so that the damage status of domestic sites can be promptly collected, and appropriate responses can be made. We also conduct regular disaster drills in cooperation with local fire departments to facilitate initial response in the event of an earthquake. In addition, to prepare for a tsunami disaster in the event of a Nankai Trough earthquake, which is expected to cause significant damage, we have set up evacuation sites and ensured that all employees are well informed of the situation, assuming the maximum tsunami height and minimum arrival time of a tsunami.

Preparing for a Large Earthquake

Kyocera provides disaster prevention education to all employees and encourages individuals and departments to think proactively about how to prepare for earthquakes. Through this, we are prepared to act safely during and after an earthquake. In addition, in the event of a disaster such as a large-scale earthquake that affects a wide area, it is important to quickly check the structural soundness of buildings. For this reason, we are introducing a building integrity detection system that can automatically diagnose the impact of an earthquake, and we are planning to establish a system that enables prompt evaluation at each site.

Preventing Damage to the Surrounding Community and Actively Participating in Local Disaster Prevention Activities

Kyocera conducts disaster drills twice a year, simulating earthquakes, etc., as an extension of its corporate activities, with the aim of minimizing the damage from a large-scale disaster and preventing damage to the surrounding community. Kyocera also participates in joint fire extinguisher and hydrant training sessions with the local community to acquire fire extinguishing equipment skills. As part of our community contribution activities, some of our business sites have signed agreements with the local fire department to provide facilities as temporary evacuation sites for firefighting equipment in the event of a disaster, and we are constantly considering how we can contribute to the community in the event of a large-scale disaster.

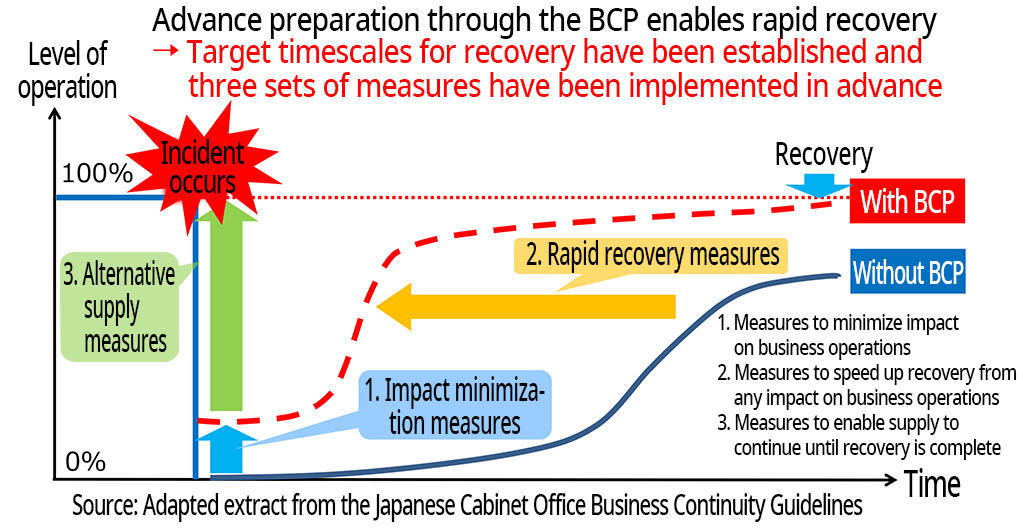

Maintenance and Early Restoration of Business Activities

The Kyocera Group has adopted a policy aimed at the swift recovery and resumption of operations in the event of a disruption in the supply of products and services due to disasters. We are engaged in Business Continuity Management (BCM) initiatives. In Japan, we have formulated a Business Continuity Plan (BCP) with a focus on the occurrence of earthquakes as a major disaster. In terms of equipment, we take measures such as securing important equipment, arranging repair materials, and ensuring alternative production. Additionally, we conduct BCP education and training for employees once a year. We also conduct management reviews of each department's activities and continuously make corrections and revisions. In recent years, the risk factors threatening business continuity have been on the rise, including not only earthquakes but also various natural disasters such as typhoons and heavy rains, the spread of infectious diseases, supply chain risks due to international conflicts, and computer virus infections caused by malware. In addition, we respond flexibly to risks by verifying cases of business interruption and conducting ongoing reviews not only of existing BCP documents, but also of risks and countermeasures. Moving forward, we will continue our efforts to prevent and mitigate damage when risks occur and will work towards ensuring the continuous provision of products and services.

Supply Chain Related BCP Efforts

The Kyocera Group promotes evaluation of alternatives and multiple purchasing for procurement of parts and raw materials to ensure that production activities do not become stagnant in the event of a disaster. We distribute the Kyocera Group Supply Chain Code of Conduct in the Supply Chain to all suppliers to help them understand the concept of BCP. In addition, for suppliers who supply us with important parts and raw materials, we conduct more detailed checks of their BCP activities.