Kyocera

Robotic Services

Our simple, cloud-based subscription services delivers intelligent collaborative robots using AI and 3D vision.

Common problems in introducing collaborative robots

High-mix, low-volume (HMLV) manufacturing

HMLV manufacturing involves producing many different products in small quantities, which adds time, cost and labor to robot teaching requirements.

Irregular processes or parts

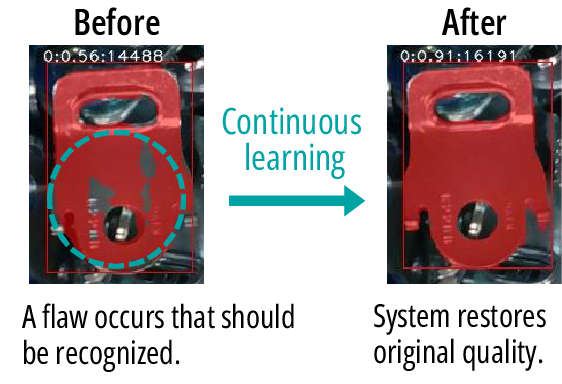

A robot taught to perform a single repetitive action cannot adapt to irregular processes or parts.

Absence of on-site robotics experts

Worksites with no on-site robotics expert generally have difficulty adjusting or adapting a robot to new work.

Concern about return on investment (ROI)

Uncertainty over ROI can derail the decision to invest in robotics technologies.

Kyocera Robotic Services can help solving these problems.

Collaborative robots that are functionally enhanced through AI and machine vision can see, think, and skillfully perform various tasks.

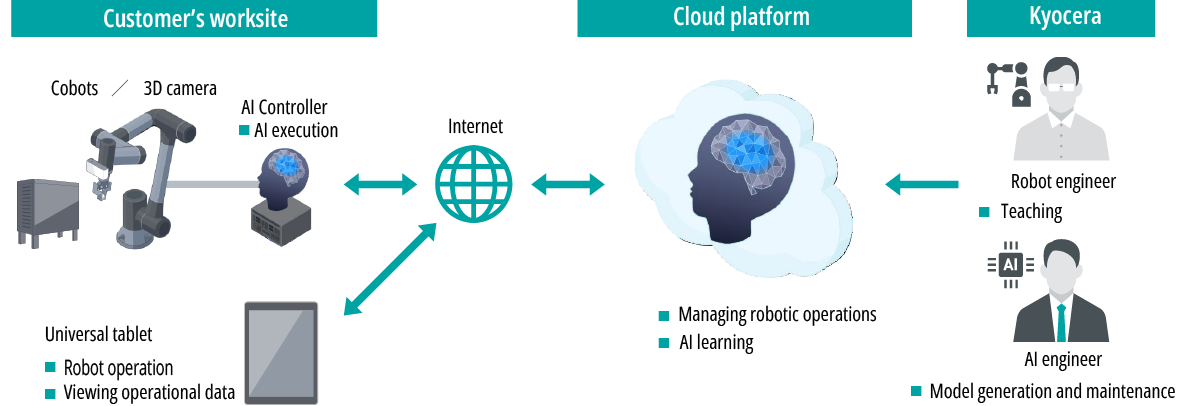

System Overview

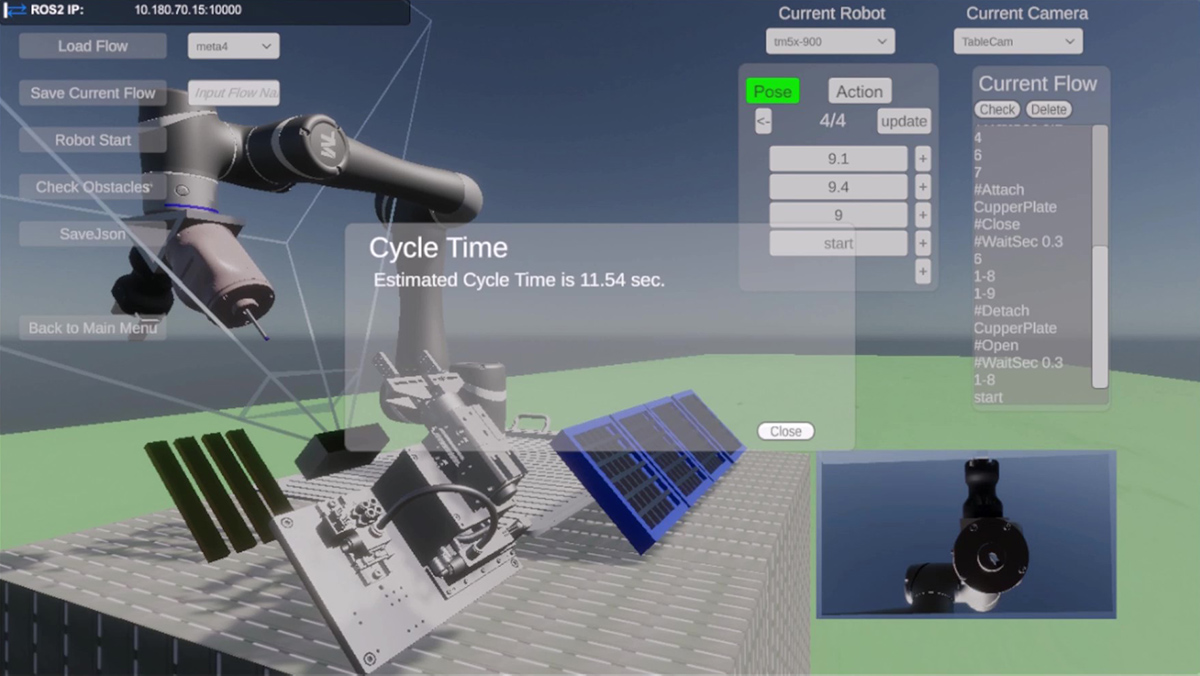

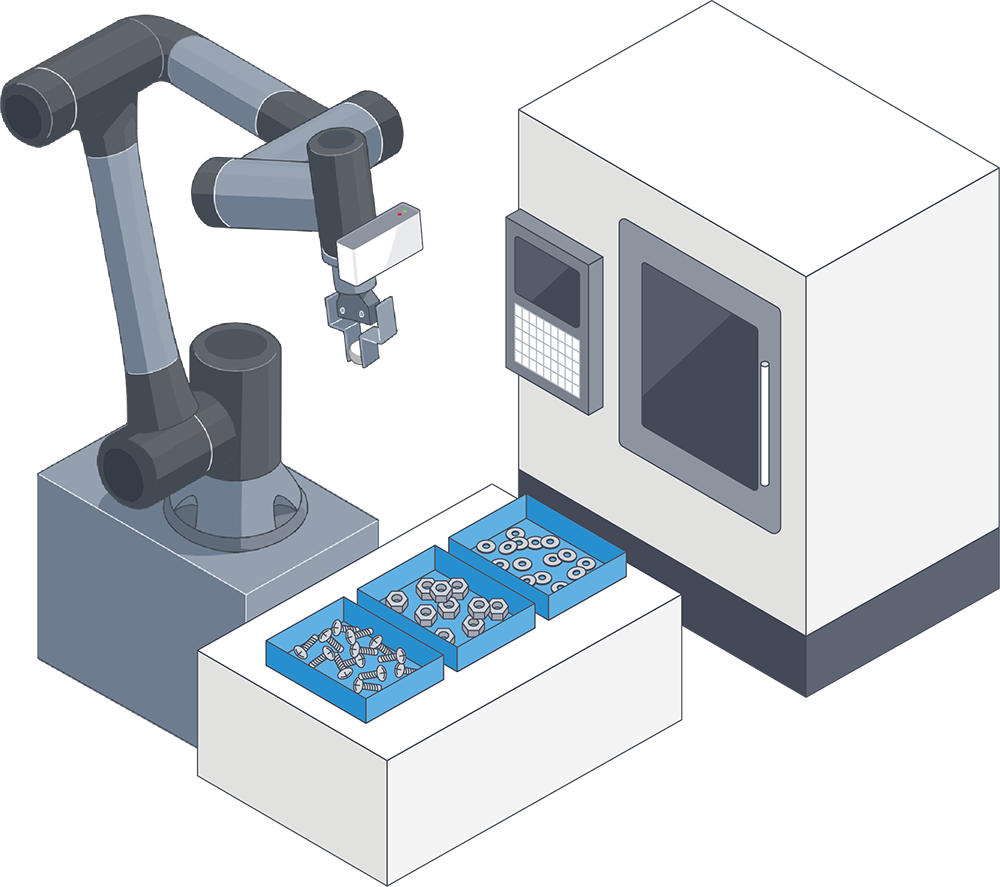

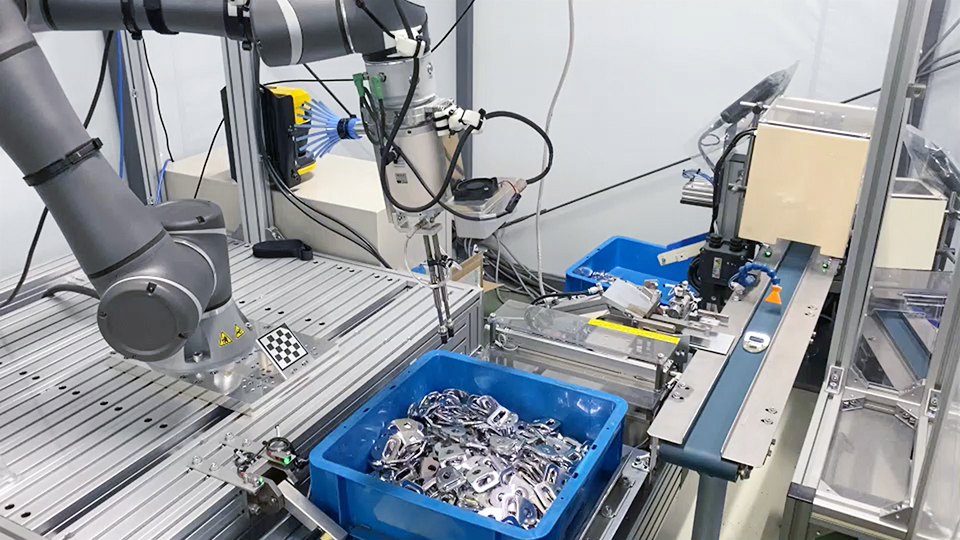

With Kyocera’s system, using a robot becomes as simple as ordering a task (“job”) on a tablet. Using our proprietary AI and 3D vision technologies, robots can handle irregular processes, such as “bin picking” parts, and using our cloud system you can give job orders to multiple robots simultaneously from a remote location.

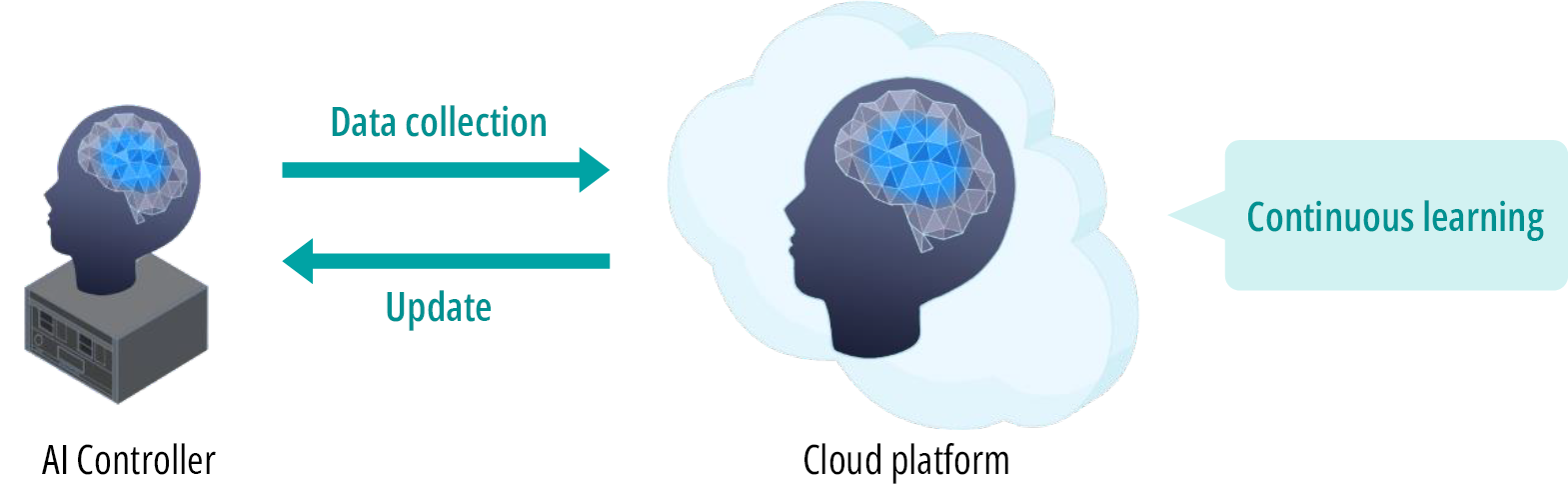

Our cloud-based services are provided by subscription, so you can easily create and update jobs, or upgrade AI models, at no additional cost.*

*Cloud-based storage capacity varies by plan.

Feature

Problem-solving features:

Kyocera Robotic Services

Making collaborative robots intelligent

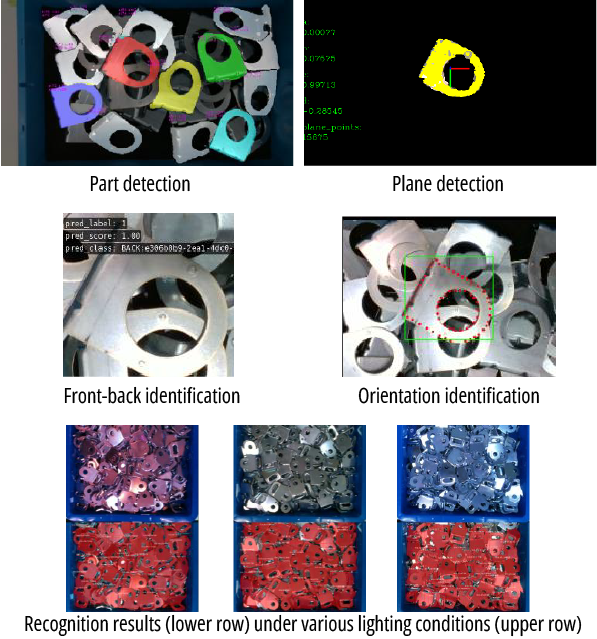

Cobots gain autonomy through AI and 3D vision, responding with a variety of movements.

No teaching required

Kyocera creates and manages all jobs and AI models, eliminating the need for customer teaching.

Easy operation

Order jobs on your tablet and manage multiple robots simultaneously

Secure flat-fee system

No initial cost for AI system, which is provided via subscription from the cloud.

- Teaching

- Continuous learning

- Fleet management

- Job management

- Bin picking

Solve

- Responds quickly to high-mix, low-volume production

- No need for dedicated robotics staff

- Compatible with irregular processes / part shapes

- Reduces implementation costs

- Teaching

services - Continuous learning

services - Fleet management

services - Job management

services - Bin picking

services

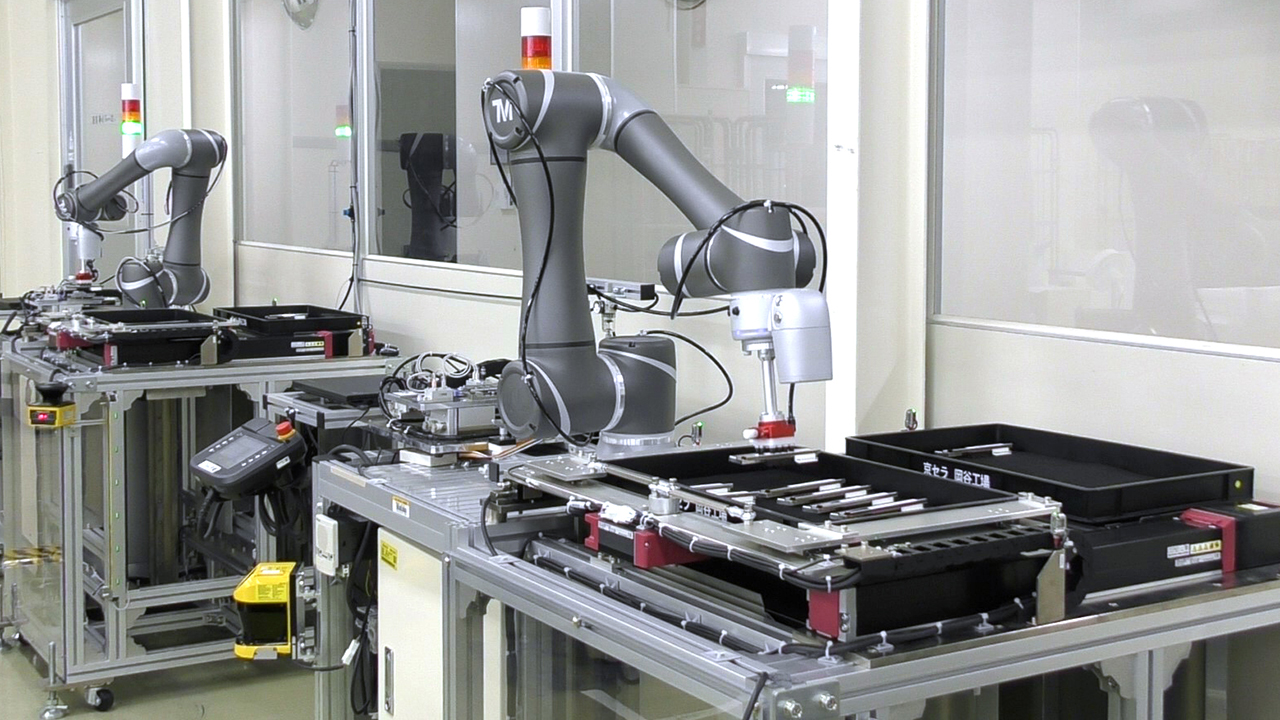

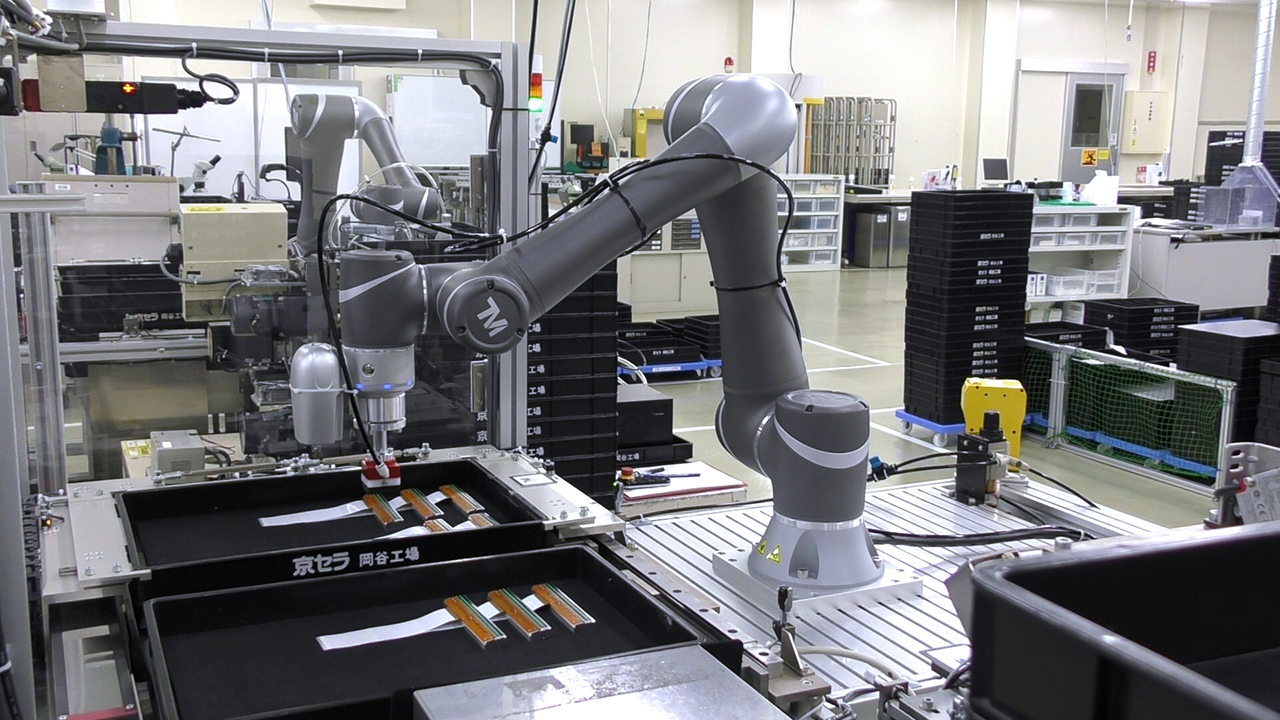

Application examples(General use)

Here are some examples of how our services are being used.

Topics

- 2023.11.20

- Exhibit at International Robot Exhibition 2023(11.29~12.2)

Please contact us if you have any questions.

Because this product and technology are currently in development, we may not be able to respond to all requests.