Notable Moments

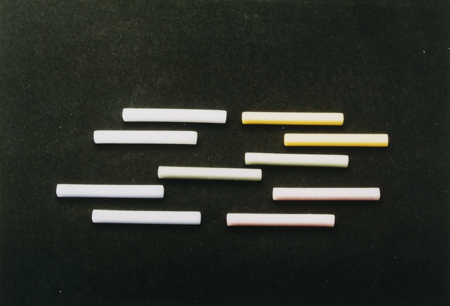

Development of multiform glass that helped Kyocera grow quickly into a medium-sized company (1960-1961)

One of the largest challenges Kyocera faced in the early days was multiform glass. Multiform glass began to be used in Europe and North America around 1960 instead of U-Shaped Kelcima as an insulating material for electron guns, and there was talk that Matsushita Electric Works would soon make the switch as well.

At that time, Kyocera's production of U-Shaped Kelcima had increased to 500,000 units per month, making it a mainstay product, but conversely Kyocera's business would suddenly be in turmoil if these orders were to disappear. Inamori felt uneasy about relying on one product, and soon started developing multiform glass.

However, Kyocera did not have the technology or equipment to make glass. Inamori procured samples and started research, borrowing a furnace for melting glass at a glass manufacturer he did business with. Inamori went to their factory when it shut down for the day, melted glass with their equipment all night, and took it back to Kyocera for molding. Despite lacking the technology and equipment, Inamori was driven by his sense of urgency, persevering through trial and error to achieve commercialization in just eight months.

Other glass manufacturers began marketing their finished products around the time Kyocera completed its multiform glass, but - thanks to orders from Matsushita Electric Works - Kyocera was able to win business from other companies as well. Kyocera gradually expanded its sales channels, and at its peak accounted for more than 85% of demand in Japan.