Notable Moments

Development of the cathode-ray tubes that supported Kyocera around its founding (1959)

Although orders for the U-shaped Kelcima were coming in steadily, it was clear that sales would stagnate once the rapid growth in TV demand plateaued. Inamori therefore took the initiative to lead the sales activities program.

At that time, most of the electronic components used in appliances such as televisions and washing machines were imported from Europe and North America. When Inamori made sales visits to electrical and electronic component manufacturers, he was often asked if Kyocera could make such parts, as most of those products were not made in Japan. Inamori immediately replied that Kyocera could make them, and embraced the challenge of delivering on his commitments. He did so because the only way Kyocera - a new entrant - could gain credibility was to achieve what rivals could not. This approach reflected his belief and fierce passion that whatever could be made overseas could also be produced by Kyocera.

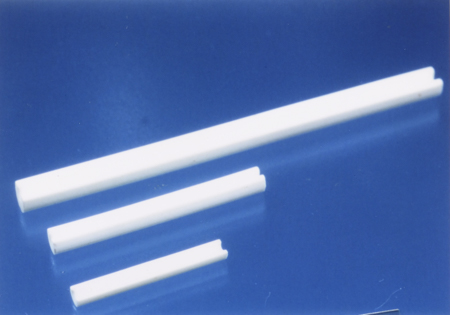

Inamori saw enormous possibilities in fine ceramics, and encouraged his employees by saying, "Even if the market doesn't exist now, this product will be needed someday," accepting even challenging orders to expand the applications and possibilities of ceramics. One of these was the cathode-ray tubes for television picture tubes that Matsushita Electric Works ordered in May 1959.

Everything from materials to molding, firing, and processing had to be developed independently, and Kyocera had not yet produced a product made from alumina. Despite the enormous challenge, Inamori accepted the order, and worked on development with samples from Philips.

The most difficult part of manufacturing was cutting the extremely-thin tubes. Hollow cathode-ray tubes will be crushed by a blade if touched before firing, and will break after firing. After much trial and error, Inamori and his team devised a method in which melted liquid wax is poured into a fired cathode-ray tube, cooled, and cut while the cavity is filled with solidified wax. After cutting, the tube is warmed to melt the wax, completing production.

This cutting method was used to process various other parts, and even registered as a utility model, a simple form of patent. The completed cathode-ray tubes contributed to the company's early business performance, and Matsushita Electric Works rated it as better than Philips products.