Technology

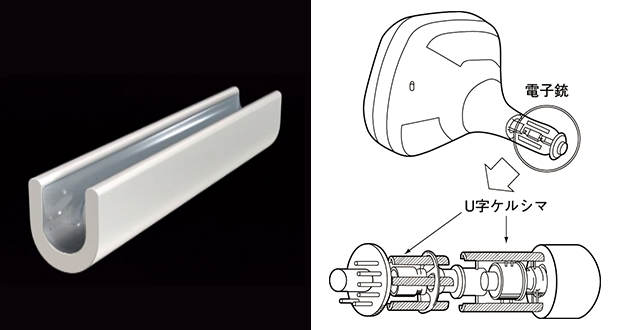

U-Shaped Kelcima

The U-shaped Kelcima, a vital insulating component used in early TV picture tubes, had been procured by Japanese TV manufacturers from suppliers in Europe and America. In 1955, Inamori became the first in Japan to successfully mass-produce the ceramic U-shaped Kelcima. This component was made from forsterite, a ceramic with high-frequency insulating properties. The following year, Inamori himself succeeded in creating highly-pure synthetic forsterite in a lab, becoming the first in Japan to do so.

The biggest technical challenge in commercializing the U-shaped Kelcima was powder molding.

Traditional insulators were formed by mixing clay into powdered natural minerals. However, for optimal high-frequency insulation, the fine metal oxide powders should not be diluted or mixed with other minerals. Unfortunately, when powdered, metal oxides become dry and tend to remain particulate instead of solidifying under pressure. Inamori initially molded the components by traditional methods, using minimal clay and water as binders. At the same time, he wondered whether it could be possible to sinter pure metal oxides with no clay, to enhance insulating performance under high-frequency conditions. He conducted experiments every day.

He then made a breakthrough with the discovery of a new binder in an unexpected way.

One day, Inamori stumbled upon a lump of paraffin wax under his laboratory table. Annoyed that it had been left there, he tried to retrieve it, but the wax stuck to his shoe. Paraffin wax is a product of oil refining. It solidifies at room temperature and melts when heated. It is also used as a raw material for candles.

The wax sticking to his shoe inspired Inamori to try paraffin wax as a binder for his forsterite powder. When the two were mixed and heated, molding the forsterite powder became very easy. Best of all, during the firing process, the wax cleanly evaporated from the mold, resulting in ceramics consisting of pure forsterite. Inamori thereby succeeded in manufacturing a U-shaped Kelcima made of forsterite that exhibited outstanding insulation properties even in a high-frequency environment.

Seeing the commercialization of the material he had developed gave Inamori a great sense of accomplishment and fulfillment as an engineer. The development of this material and related manufacturing technologies became the basis for Inamori's founding of Kyoto Ceramic Co., Ltd. (now Kyocera).

(Left) U-shaped Kelcima / (Right) U-shaped Kelcima mounted within a cathode-ray tube