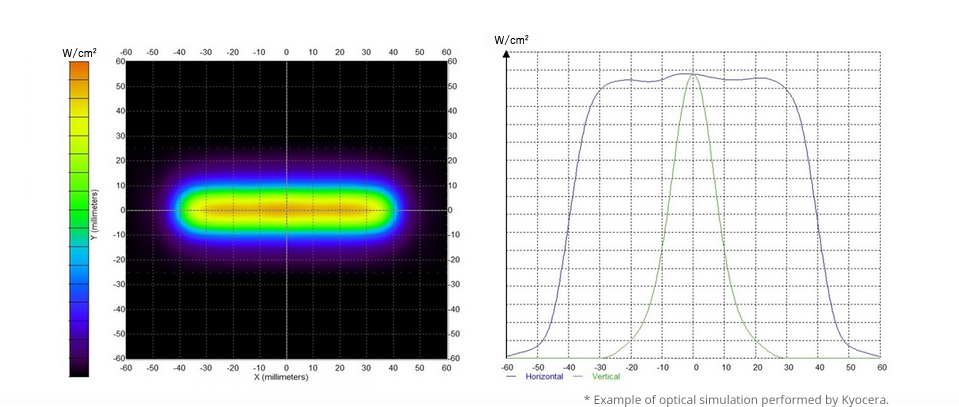

Characteristics of Kyocera UV LED Light Sources

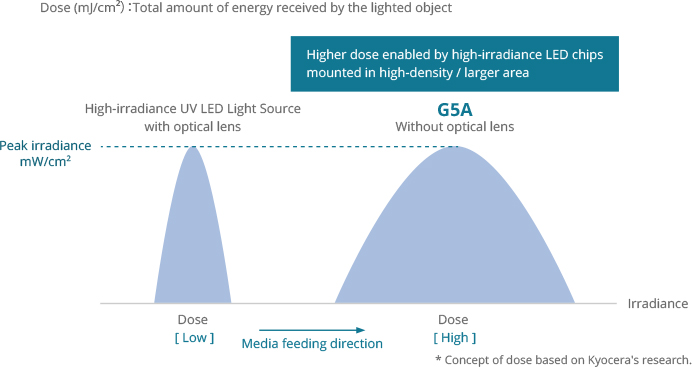

High-density mounting of LED chips produces high-output irradiation. Kyocera's low-thermal resistance ceramic substrate improves heat dissipation and allows high density mounting of LED chips.

Sheet-Fed Offset Printing

Sheet-fed offset printer with chain delivery system that requires long working distance for curing and pinning.

Sheet-fed offset printer with chain delivery system that requires long working distance for curing and pinning.

Inkjet Printing

Pinning and curing for UV inkjet single-pass and multi-scan printing.

Pinning and curing for UV inkjet single-pass and multi-scan printing.

Other Analog Printing

Curing for offset rotary printers, flexographic printers, and screen printers.

Curing for offset rotary printers, flexographic printers, and screen printers.

Coatings

Curing various coating materials such as for optical fiber, wood, and mobile phone cases.

Curing various coating materials such as for optical fiber, wood, and mobile phone cases.

Adhesives

Curing UV curable adhesives such as for LCD, touch screens, and substrate manufacturing.

Curing UV curable adhesives such as for LCD, touch screens, and substrate manufacturing.

Exposure Devices

Photo processing for semiconductor manufacturing equipment, pattern forming for LCD panels, and circuit forming for PCB.

Photo processing for semiconductor manufacturing equipment, pattern forming for LCD panels, and circuit forming for PCB.

High-density mounting of LED chips produces high-output irradiation. Kyocera's low-thermal resistance ceramic substrate improves heat dissipation and allows high density mounting of LED chips.

3 units of G5A connected

| Model | Cooling method |

Dimensions W × D × H (mm) |

Weight (kg) |

Irradiation window size (mm) |

Wavelength (nm) |

Dose(mJ/cm2) at 50m/min WD = 10mm |

Peak irradiance (W/cm2) |

|

| WD=0mm | WD=10mm | |||||||

G5A  |

Air-cooling | 80.3 × 88.0 × 150.5 | 1.0 | 80 × 20 | 365 | 200 | 16 | 6 |

| 385 395 |

270 | 24 | 8 | |||||

WD: Working Distance

G5A Model Data sheetPDF(530KB)

*According to the survey of other available product in the market by Kyocera.

G5H

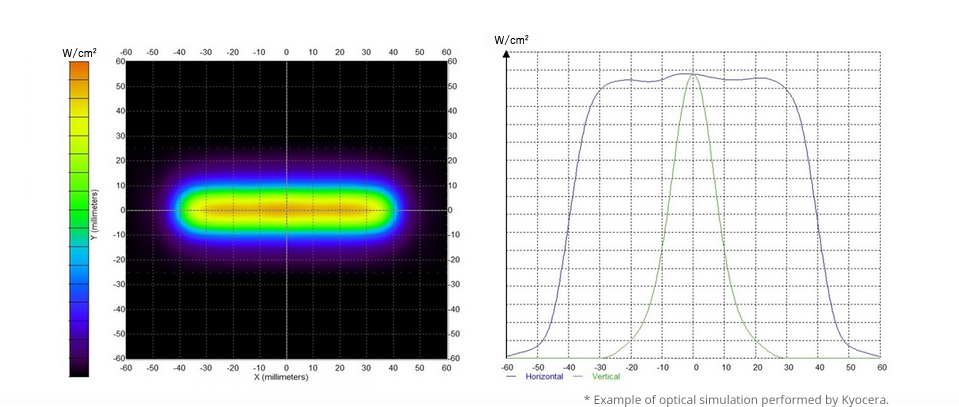

At 50m/min transportation speed with UV wavelength 385nm/395nm

| Model | Cooling method |

Dimensions W × D × H (mm) |

Weight (kg) |

Irradiation window size (mm) |

Wavelength (nm) |

Dose(mJ/cm2) at 50m/min WD = 10mm |

Peak irradiance (W/cm2) |

|

| WD=0mm | WD=10mm | |||||||

G5H  |

Air-cooling | 80.3 × 140.0 × 170.5 | 1.5 | 80 × 31 | 365 | 300 | 16 | 9 |

| 385 395 |

400 | 24 | 12 | |||||

G5H Model Data sheetPDF(333KB)

G5AP

![[ Without Pinning ] Example of unwanted ink spreading

and color mixture (lower print quality)](/prdct/printing-devices/design/img/led-uv/led-uv-p16.jpg)

![[ With Pinning ] Example of pinned color inks

(higher print quality)](/prdct/printing-devices/design/img/led-uv/led-uv-p17.jpg)

| Model | Cooling method |

Dimensions W × D × H (mm) |

Weight (kg) |

Irradiation window size (mm) |

Wavelength (nm) |

Dose(mJ/cm2) at 50m/min WD = 10mm |

Peak irradiance (W/cm2) |

|

| WD=0mm | WD=10mm | |||||||

G5AP  |

Air-cooling | 120.0 × 19.0 × 219.0 (D=35.0 at fan area) |

0.5 | 120 × 13 | 365 | 25 | 4 | 1 |

| 385 395 |

35 | 6 | 1.5 | |||||

G5AP Model Data sheetPDF(502KB)

G5AN

G5HN

| Model | Cooling method | Dimensions W × D × H (mm) |

Weight (kg) |

Recommended nitrogen purity | Nitrogen flow rate (L/min) |

G5AN  |

Air-cooling | 80.3 × 109.7 × 161.2 | 1.3 | Higher than 99.9% | 10~30 * May vary by the used UV ink and printing conditions |

*Irradiation window size, UV Wavelength, Dose, and Peak irradiance are same as G5A model.

| Model | Cooling method | Dimensions W × D × H (mm) |

Weight (kg) |

Recommended nitrogen purity | Nitrogen flow rate (L/min) |

G5HN  |

Air-cooling | 80.3 × 161.7 × 181.7 | 1.8 | Higher than 99.9% | 10~30 * May vary by the used UV ink and printing conditions |

*Irradiation window size, UV Wavelength, Dose, and Peak Irradiance are same as G5H model.

G5AN Model Data SheetPDF(399KB)

G5HN Model Data SheetPDF(387KB)

Please contact us if you have any questions about Kyocera UV LED Light Sources.